Mica refers to a group of 37 naturally occurring silicate minerals known for their layered, plate-like structure. The most commercially valuable types are muscovite and phlogopite.

Block mica produces large sheets, peeled and cut for industrial applications.

Flake and scrap mica

are ground into fine powders used across multiple industries.

Valued for its reflective, insulating, and heat-resistant properties, mica plays a vital role in many sectors, from electronics and construction to cosmetics and automotive manufacturing.

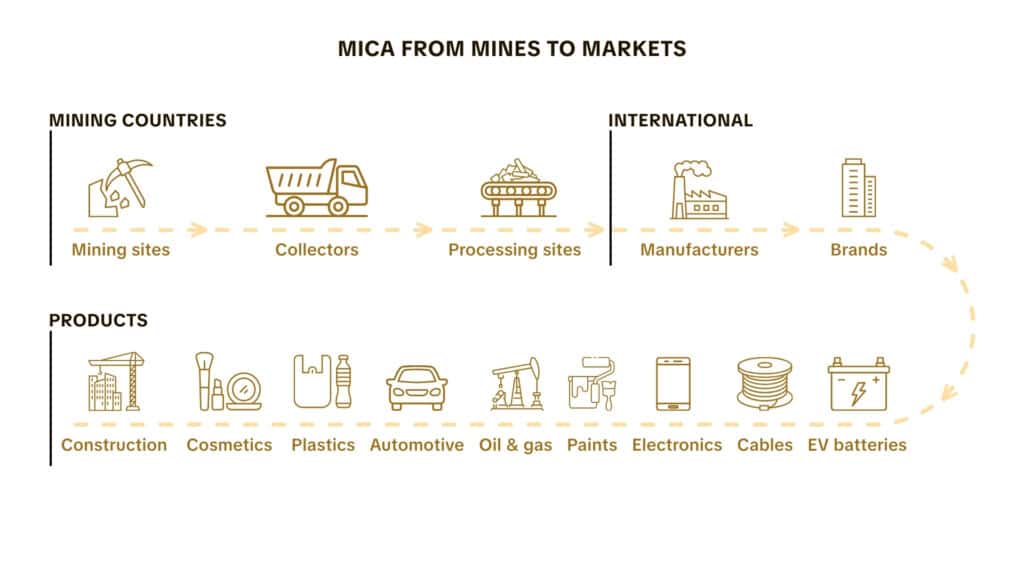

Mica from mines to market

Mica’s versatility stems from its unique combination of optical, electrical, and thermal properties. It is used in a wide range of applications across multiple global industries.

Ground mica acts as a filler and extender in joint compounds and gypsum wallboard, improving flexibility and preventing cracking.

Thanks to its natural shimmer and reflectivity, mica creates the pearlescent effect in makeup, body glitter, nail polish, shampoos, toothpaste. It is a core ingredient in many more beauty and personal care products.

In the plastics industry, mica enhances lightweight insulation, sound absorption, and impact resistance in vehicles. It also adds strength and shine as a pearlescent pigment in molded parts.

Mica’s reflective properties create distinctive pearlescent finishes on cars, boats, trucks, aircraft, and industrial equipment. It also improves durability, corrosion resistance, and consistency in coatings.

Ground mica functions as a lubricant and sealer in drilling fluids, helping fill porous formations and stabilize boreholes.

Mica appears in nearly every stage of vehicle manufacturing – from paint and coatings to plastics, insulation, brake linings, electrical battery packs, and rubber components. Phlogopite mica is especially prized for its heat resistance.

Due to its dielectric strength – an ability to withstand electric current, mica is used in capacitors, transformers, semiconductors, and circuit boards, as well as in household devices like hair dryers and heaters.

Ground mica and mica paper provides fire and heat-resistant insulation for electrical cables and wiring.

Fabricated muscovite mica is increasingly used in battery insulation systems, including electric vehicles (EVs) and renewable energy storage.

While mica is mined on every continent, the largest volumes come from India and Madagascar, followed by Brazil, the US, Malaysia… With mica demand increasing, driven by the energy transition, new countries are also exploring mica extraction opportunities (Nigeria, Namibia, Tanzania, etc.)

In India and Madagascar, mining often takes place in informal or unregulated conditions. Communities depend heavily on mica for income but lack access to education, healthcare, and government services. The absence of effective regulation allows illegal mining and child labor to persist in the supply chain. Most mica miners earn only a fraction of what would be needed to reach a living wage and work under fair conditions.

Multiple interconnected factors contribute to these challenges:

One cause of the prevalence of child labor, poor working conditions and poor livelihood situation stems from the poor enforcement of a legal framework for the mica mining sector.

Mica-mining communities remain politically and socially marginalized, with limited capacity to influence labor practices or local development.

Mica-mining regions generally face severe shortages in schools, teachers, and healthcare facilities, perpetuating cycles of poverty and dependence on informal mining.

Limited infrastructure and agricultural potential make mica mining one of few livelihood options. Some intermediaries and unregulated operators often exploit this dependency.

Economic hardship pushes women and children into mica collection. With few childcare or schooling alternatives, entire families become dependent on mica, reinforcing a cycle of poverty and child labor.

Political instability and governance challenges weaken law enforcement and often make it difficult for authorities to provide essential public services in mining regions.

An electric car may contain up to 15 kg of mica, while an electric bus can require up to 70 kg for battery insulation.

The material’s natural safety and insulation properties make it a key component for EV batteries, cables and other high-performance applications.

Additionally, mica is being adopted as a safe, sustainable alternative to certain restricted cosmetic ingredients.

Synthetic mica replicates many of the same properties as natural mica, including heat resistance, electrical insulation, and light-reflective qualities, while allowing tighter quality control and reducing dependence on mining.

In addition to natural mica, synthetic mica is manufactured in laboratories to provide a consistent, high-purity alternative for industrial and cosmetic applications. Synthetic mica replicates many of the same properties as natural mica, including heat resistance, electrical insulation, and light-reflective qualities, while allowing tighter quality control and reducing dependence on mining. It is increasingly used in cosmetics, electronics, and high-performance coatings. Nevertheless, synthetic mica is made of different mineral compounds – whose sourcing should also be questioned – and obtained from an extremely energy-intensive transformation process. Both its social and environmental footprint should therefore be assessed.